Read about the remake of the classic Udat case.

|

The second half of the mounting mechanism for the heatercore was completed. Simply some square aluminium profiles riveted to ventilation duct termination

and held in place by four screws going through the bottom of the case. On top of that is one of the main features of this mod, a 5" ventilation duct bend.

The duct couldn't face the copper panel at a straight angle due to the shape of the front beezel. The solution was this this strange piece made out of

another duct termination. You can now see why the fan got reshaped.

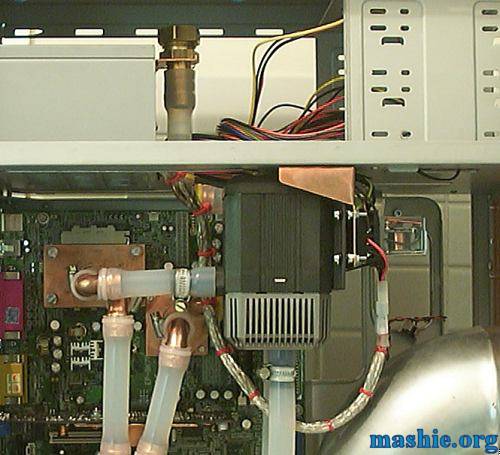

Another testified of the completed duct to measure where the hole should be cut in the copper panel. Also the assembly of the waterloop has started. Due to

the silicone tubing refusing to bend nicely soft copper bends were used all over for a tight fit. The T connector is for the filler tube.

The hole in the copper plate cut with the best modding tool ever, a hand nibbler. It is hard to beat the accuracy of the cut not to mention Dremels truly

suck in copper. As long as you use a glove you will get away without blisters.

The copper plate was put in place to verify all measurements and cuts actually ended up as planned.

The motherboard tray was modified to gain access to the screws holding the waterblocks without removing the whole motherboard in the process.

To keep the waterloop compact the pump was mounted hanging at the top in a custom made copper bracket. To initially fill the system with water was an

interesting experience. After the whole loop was filled it has been working like a charm for nearly four years.

The filler cap at the top is normally resting in the fork shaped holding device as seen here. When topping up the system it can be unhooked and bent to

the side to permit filling outside the case. To the right of the pump is a small 12V relay controlling the 220V pump so it only runs when the computer is on.

|

| All trademarks used are properties of their respective owners. All rights reserved Copyright © 2002 - 2020 by Mashie Design |